How Fort Vale Engineering leads the way in the design and manufacture of valves and fittings for transportable tanks

Fort Vale Engineering Limited (Fort Vale) was formed in 1967 by Ted Fort, in Colne, Lancashire, who went on to receive an OBE for services to industry. “From a small building and three people, we steadily grew to occupy increasingly larger buildings in Nelson, Lancashire,” begins Ian Wilson, Managing Director. “With a workforce that was growing in both size and skillsets, I joined the company in 1978. In 2008, the business moved its head office and manufacturing facility to new, state-of-the-art premises in Simonstone, Lancashire, which is where we are now. It’s a 75-acre site, on which we have 30 acres of industrial planning, and the remainder is brownfield acreage. We bought the site in 2006 and moved in two years later. The main factory building already existed, but we did a lot of work to bring it up to standard, including building a brand-new office block.

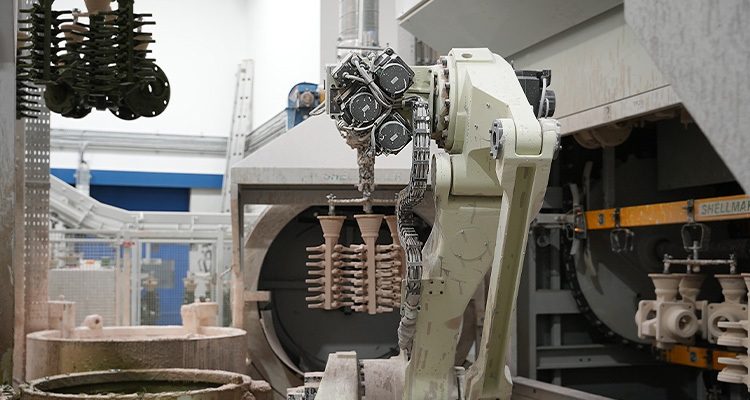

“We’ve since constructed a research and development building, in which we not only conduct our research and development activities, but also house our tool room where we make all our own jigs and fixtures and operate a small division that does work for the nuclear industry. Following expansion, we added another bay to the existing building. We also have a foundry on-site to complement our manufacturing capability and have built a semi-automated warehouse. We’re currently building a new assembly factory which is due to be completed in August 2024.

“We’ve since constructed a research and development building, in which we not only conduct our research and development activities, but also house our tool room where we make all our own jigs and fixtures and operate a small division that does work for the nuclear industry. Following expansion, we added another bay to the existing building. We also have a foundry on-site to complement our manufacturing capability and have built a semi-automated warehouse. We’re currently building a new assembly factory which is due to be completed in August 2024.

Award-winning operations

“Additionally, we decided to add a sports and gym facility to the site for our workforce to use free-of-charge. It’s important to us to give back to our employees in terms of tangible benefits. With a plant that operates 24/7 and a workforce of over 400 people on rotating shifts, good employee health is important to us. We strive to enable our workforce to be fitter and healthier than ever before. They are one of our biggest investments for the future.”

Fort Vale is the world leader in the precision manufacture of valves and fittings for the transportation of bulk liquids in the tank container, road tanker, and rail industries. The transportation of gases and liquids by road, rail, and sea must be safe. As such, the company works with industry and regulatory bodies to ensure its quality of design, materials, and manufacture makes first-class safety a reality.

“We don’t make the tanks themselves but supply the valves and other ancillary equipment. With the globalization of goods transportation, one of our biggest markets is tank containers. These have a carbon steel frame but within that frame, there is a big stainless-steel barrel, and we provide all the valve gear that’s needed to equip those barrels. Most international liquid transportation uses these tanks and it’s a very safe method. We provide the safety devices for all these tanks. It’s a very niche global market and we occupy about 80 percent of it. We export approximately 95 percent of everything we make and have received the Queen’s Award for Export four times. We’ve also applied for the King’s Award this year, so fingers crossed, we’ll achieve that.”

Local presence

With a huge range of products to suit all liquid tank classifications, from food to high-hazardous materials, and a dedicated range of equipment for T50 compressed liquefied gas tanks, the company also has the flexibility to help with bespoke design requirements as well as being able to manufacture large batch quantities of tank equipment sets. Fort Vale manufactures the most extensive range of road tanker equipment available in the industry for the diverse requirements of ADR and non-ADR road tankers. As tanker technology becomes more sophisticated, the company is responding with valve systems designed to suit the increased safety features demanded by the market. Fort Vale equipment is easy to use, simple to maintain and supported worldwide.

The company’s goal is to be not only the preferred supplier of new OEM equipment but also the premier after-sales supplier for spares. To this end, Fort Vale has offices and stock in the UK, USA, Holland, Singapore, Australia, and China, as well as authorized distributors located around the world.

“In terms of our activities, China is a big market for us. We have a factory there and produce parts for local customers who build tanks. Indeed, 85 percent of the world’s tanks are built in China, so it’s very important for us to be near to these customers. It makes sound sense to have a local presence to help mitigate supply chain disruptions and provide a quick and reliable service.

Exacting standards

“We also supply a lot of equipment for the rail transportation market in the US, primarily for crude oil. Putting down a pipeline can be prohibitively expensive, so rail cars are a more viable option. The rail wagon market is a highly diverse sector, both in terms of customer specifications and geographical operating conditions. Our many years of experience in designing valve solutions for liquid and gas transportation has enabled us to produce a range of robust valves and access equipment, with versions that suit the requirements of the European and American markets. Our equipment has also been widely used on tanks transporting and storing chemicals, fuel, acids, and waste cargoes in the offshore drilling industry,” he explains. “We have recently developed a range of valves to meet the requirements of the European rail car industry and have been successful in winning a significant proportion of this market.”

Fort Vale is synonymous with excellence in engineering and the company takes pride in being at the cutting edge of technology. With its state-of-the-art manufacturing facility, the company has total control over all processes from research and development, design, investment casting, pressing, forging, plasma, and laser cutting to assembly, testing and certification. Multiple in-house test facilities are suitable for the full range of products from impact testing, air and liquid flow tests to high pressure testing for gas valves.

manufacturing facility, the company has total control over all processes from research and development, design, investment casting, pressing, forging, plasma, and laser cutting to assembly, testing and certification. Multiple in-house test facilities are suitable for the full range of products from impact testing, air and liquid flow tests to high pressure testing for gas valves.

“We design all our own products and continually develop new products and improve on the design of existing ones. We also have very sophisticated test equipment to ensure the quality of our products and their adherence to exacting specifications. To do so, we work with a lot of different inspection bodies around the world.

Support and service

“As an organization,” Ian continues, “we are committed to training and innovation. These are key elements of the Fort Vale philosophy. We believe that hard work, the best training, and innovation using the best facilities and people are the cornerstone of our success. For over 50 years, we have been training approximately eight apprentices every year. It’s a formal four-year course, so, we currently have about 32 young people going through the process. At the end of their training, they will have respected qualifications and be a skilled operator. Several will stay with the company. In fact, three of my directors started here as apprentices. We always believe in promoting from within wherever we can. Many of these young people end up in management roles and do vital work for the company, while earning a good living.

“I think we do things right here. We not only listen to and learn from our customers, but we also act on their feedback to offer a reliable and quality service. People have confidence in our products. I’ve got an excellent team of people here. We foster an informal environment with a family feel. I know most of the people on the shop floor by name and they all know me. We have a very good relationship with our people and meet representatives from each section every month to talk through any issues. Our people want to do a good job and they want to make the company successful.

“Our growth has been organic; in that we’ve created more products in response to an expanding market, but we’ve also been proactive. We go to exhibitions and seek out opportunities to bring new products to the market as well as to penetrate new markets. We never really set out to become big, to be honest; we always wanted to be successful, and growth tends to be a byproduct of that success,” he concludes.

Hard work, dedication, and innovation; coupling those core values with its industry-leading safety, precision and quality gives Fort Vale an advantage over its competitors. The company has always believed that the best way to lead is from the front, by setting an example, by being leaders, not followers. The development of its people brings continuity to Fort Vale’s approach, ensuring support and service to customers for years to come.