Barnes Technical Products

Barnes Technical Products can design and build custom equipment for a range of fields.

Russell Barnes founded BTP in 1984 in West Haven, Conn., after stints in sales/engineering and as a manufacturer’s representative. “Then someone asked me to manufacture something for them,” Barnes says. “I have an engineering background. My family was in the machining business. I grew up around machinery. My mom and dad are both engineers.”

BTP designs everything from simple hand tools to full continuous motion assembly machines “and everything in between,” the company says. BTP creates products for individuals, small companies and large household name companies. Along with design/build, the company offers welding, CNC machining and 3D computer aided design services.

“A customer wants to accomplish something but doesn’t know how to do it,” Barnes says. “We create a solution, get approval and build it for them.”

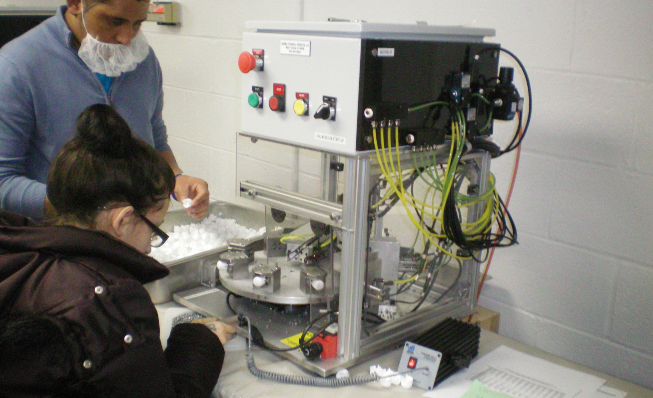

Over the last 35 years, BTP has worked with several industries. The company has helped food processing and personal care companies to develop custom equipment for their plants and laboratories; helped pharmaceutical companies develop custom vial holders, chilled racks and inert gas chambers for liquid handles and filling; and developed equipment and machinery that manufacturers use to help produce and test their products.

In 2012, BTP began to invest in CNC machines. Today, machining accounts for 40 percent of their business.

Prototype and Turnkey

Among BTP’s clients is a manufacturer of pressure gauges that requested a machine that would assemble a rim, clear cover, gasket and housing. “We designed a six-station indexing machine that will press the components together, while rotating them, and roll over a hem sealing them together,” Barnes explains.

More recently, a global supplier of cable and antennas asked the company to design a heavy-duty extension table to assist in the loading and unloading of 150-pound molds for a press. “Within a month we designed and built the roller table which has a draw that pulls out 40”, allowing the mold to be loaded into the press and them moved back out of the way,” Barnes says.

A firm that sells loss prevention and alerts equipment to retailers approached BTP about creating a custom chassis for a printed circuit board and components. The piece would be used for a device that communicates with a camera or call button or floor mat. A message would then be transmitted from those devices to a two-way radio used by a retail employee.

BTP designed a chassis and now manufactures the entire device and ships it. “That’s new for us, getting involved in turnkey,” Barnes says. “Normally we design and build a piece of equipment. One or two and that might be it. We are open to doing turnkey now. We have the expertise not only to design and build but can help bring a product to market. We would like to grow, help people with new products they want to bring to market.”

Concept to Equipment

There is not a lot of competition in the design field. “There are other companies that do this but it tends to get more specialized,” Barnes says. “You can’t easily send it offshore. You have to interact with the customer and go to the customer’s facility and look at their processes.”

BTP helps clients go from general concepts to specific equipment. “We work with people in manufacturing who are familiar with the manufacturing floor and processes,” Barnes says. “They have a pretty good idea of what they want to accomplish such as assembling a certain number of pieces per minute. They might have a general idea of how to accomplish that. The specifics and design and putting it all together is where we help them.”

The same with clients in the pharmaceutical or bio-medical fields. “Some pharmaceutical facilities may want to chill test tubes or heat a test tube block and shake it.” Barnes says. “They know the process they want and we can help them make the actual piece of equipment.”

BTP employs 10 people with backgrounds in engineering, computer aided design, manufacturing and assembly. To retain quality employees, Barnes is flexible. One employee followed his wife to South Korea. “We supplied him with a design program and CAM program for programming CNC machines on his laptop,” Barnes says. “We send him design work and he programs it and sends it back.”

Employees tend to stick around. The current staff has been employed from four to 25 years. “I’m kind of proud we have a workforce that stays,” Barnes says. “It’s a good workforce. I’m proud that we can continually come up with creative solutions.”

Goals

Over the years BTP has had to adapt. The industries in which BTP works have seen an increase in automation and programmable logic controllers, a type of industrial digital computer adapted for the control of manufacturing processes such as assembly lines or robotic devices. “Years ago, you would have air cylinders to move something from one position to another,” Barnes says. “Now, in addition, you have servo-actuators that can control the precise positioning of pieces of equipment.”

While business is steady, the biggest challenge on the design side is maintaining sales. “It’s custom equipment,” Barnes says. “It’s not like we have a product we are continually receiving orders for. A customer will buy a piece of equipment for a product they are making they are not going to have a new product every month. They may have two product lines they want to improve in a year.”

To keep their presence known, Barnes uses online sites such as Thomasnet.com and LinkedIn along with their own website.

For the future, BTP would like to expand in turnkey product manufacturing while continuing to help design and build prototypes for clients who need them.