Eurocell PLC

Proving there’s a better way

Since it was founded in 1974, Eurocell has developed products to meet both the aesthetic and energy efficiency needs of architects, specifiers, fabricators and homeowners alike

Having already established itself as the UK’s biggest manufacturer, recycler and distributor of UPVC products for the home, it was in 2015 that Eurocell took the decision to list itself on the London Stock Exchange through an initial public offering (IPO). “Since the IPO, we have enjoyed a sustained period of strong growth, which has been driven by the expediting of a clear  strategy,” explains Eurocell’s Chief Executive Officer, Mark Kelly. “This strategy has resulted in excellent progress for both our branch network and our window profiles business.”

strategy,” explains Eurocell’s Chief Executive Officer, Mark Kelly. “This strategy has resulted in excellent progress for both our branch network and our window profiles business.”

In the former, the company has successfully opened up a further 30 branches in 2017, taking its total network to 190 stores by the end of the year. “We have been opening more and more branches each year as we have gained further momentum, with our basic aim being to bring our products as close to our customers, namely builders, window fitters and installers, as we possibly can,” Mark continues. “What we are doing is creating a network that delivers national coverage and our new branches are gradually filling in the geographic gaps. We recognise that our customer base tends to be made up of one man builders or small teams, and that having to travel too far to get the products they require is time out of their working days, so we want to be able to reduce the time they spend obtaining our products and therefore increase the time they are able to spend on site. By increasing our number of branches and the range of products we supply we are helping to create a one-stop-shop for these customers. Being able to get everything they need to get the job done in one place, be it windows, roof line, roofing felt and so on, we are helping to make life as simple and efficient as possible for them.”

The windows sold through Eurocell’s branch network are sourced from its fabricator base, something that has also grown in recent years with the addition of new fabricators. “One of the more unique characteristics we possess is that we don’t fabricate any windows ourselves, we only distribute our uPVC profile meaning that unlike some of our competitors we never find ourselves in direct competition with our own customer base,” Mark states. “We work hard to develop close working relationships with our fabricator base in order to ensure that they are able to supply our joint customers, whether they are new build house builders, retail installers or commercial window suppliers, with the products they require at the best possible price.”

Eurocell’s speciality is its ability to bring together its fantastic fabricating base, extensive branch network and its state-of-the-art manufacturing capabilities to maximise synergies and deliver a competitive advantage. “We have common processes across the various aspects of our business and we are constantly putting increased effort into delivering better process and production training, improving health and safety, and up-skilling our employees,” Mark adds. “At the same time, we are working hard to maintain the quality of all of our products, improve upon the logistical delivery of these and eliminate waste wherever possible. Our customers are becoming ever-more demanding, working to tighter schedules and that means that we need to be increasingly proactive. By making our entire operation more efficient and as flexible as possible we are making ourselves responsive to our customers’ needs.”

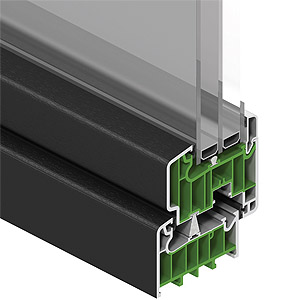

Where Eurocell also stands head and shoulders above the majority of similar businesses is in its approach to recycling, specifically the operating of its own recycling plant in Derbyshire. It is from here that the company is able to process some 40,000 old uPVC window frames per week which, once recycled, go on to be used to create a variety of new products, from thermal inserts to its own revolutionary Modus window system. Wherever possible, Eurocell offers a ‘closed loop’ service, re-engineering the uPVC taken from old frames to make new windows, doors and building products for the same supplier. This process uses less energy and gives customers a high performing, more efficient product.

“Having spent considerable time talking to both our customers and the general public, it has become increasingly clear that recycling is an issue of ever-growing importance,” Mark says. “The average lifespan of a uPVC window is around 15 years and is made from a product that is robust enough to be recycled and repurposed up to ten times. This means that the PVC in one product can have a combined lifespan of up to 150 years. Therefore, what we are doing is taking a product that previously would have found its way to landfill, something which our customers would normally have to pay to see happen, taking it out of the environment and using it to create a new, green product that benefits both the end user and the planet. We believe this is an excellent thing to be taking the lead on. From a business point of view, we have perfected our model to such an extent that we are now able to produce recycled products in a cost-effective manner, which clearly creates a commercial advantage for ourselves and means that our customers benefit from a lowering in manufacturing costs.”

Moving forward, it will come as no surprise that Mark and his team have a clearly defined strategy for growing Eurocell further still. “Firstly, we will be continuing to open up our branch network in order to achieve greater geographic coverage and to be ever-closer to our customers,” he concludes. “At the same time, we will continue to develop more profile products, increase the percentage and proportion of recycled elements that go into our products, and extend our fabricator base, all of which will be for the short and long-term benefit of our end customers.”

Eurocell PLC

Products: uPVC products