LAG Trailers

Fuelled for success

By continuously improving its production processes, LAG Trailers is aiming to become one of the top three tanker and intermodal vehicle manufacturers in Europe

Hailing from Bree, Belgium, LAG Trailers is among the most respected manufacturers of tankers and intermodal vehicles in Europe. Its history exceeding 70 years, the company has struck a balance between its young and ambitious employees and the older and more experienced staff. A collaboration of this kind ensures that the business constantly demonstrates a hunger for creating more high-quality products, coupled with the technical expertise required to manufacture them.

“Without a doubt, our people are our biggest strength,” Rob Ramaekers, CEO of LAG, begins. “The younger members of staff are a lot more dynamic, while the more senior of their  colleagues possess an exceptional knowledge and have established a long tradition of building tankers in an efficient way to satisfy the varied market requirements we encounter.”

colleagues possess an exceptional knowledge and have established a long tradition of building tankers in an efficient way to satisfy the varied market requirements we encounter.”

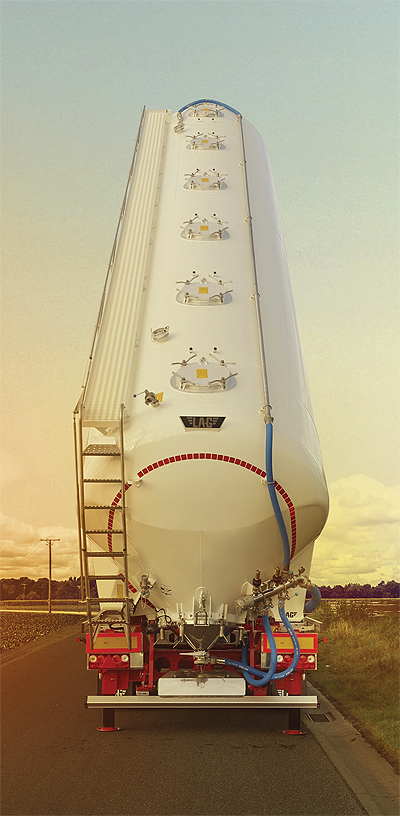

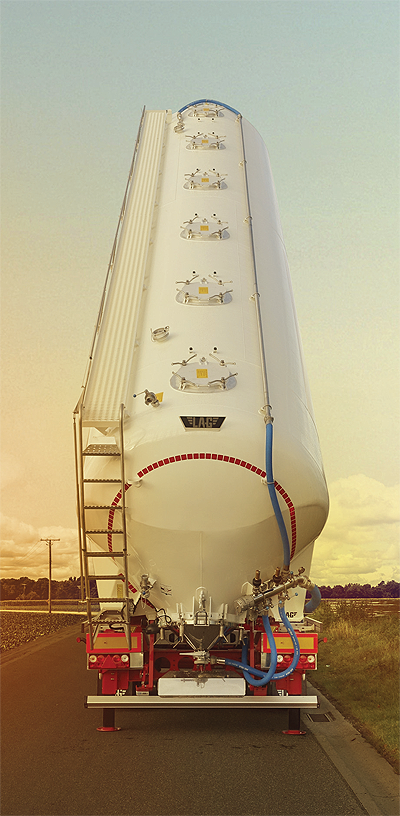

LAG’s product portfolio consists of a range of items, including fuel tankers, liquid tankers, dry bulk tankers and containers, and skeleton chassis. Out of these, it is the aluminium fuel tanker that has for a long time been the company’s flagship product. “We are the undisputed number one in the Benelux, the UK, and Poland for this tanker and repeatedly record excellent sales results in the rest of Europe. In addition, the product is also licenced to be sold in the Middle East, Asia, and Africa, and our next target is North America,” Rob comments.

Discussing the varying requirements from the different markets where LAG places its fuel tankers, Rob notes: “Clients in Belgium and the Netherlands, for example, want the vehicles to be equipped with expensive measuring devices and more complex pipework. For the UK, we usually have six compartments and the unloading/loading on the left-hand side of the tanker, while for French customers, we normally make the product with eight or nine compartments, due to the different types of fuel they contain. In contrast, the tankers for Poland and Eastern Europe normally have just four or five compartments. It is obvious that our engineering team must have the right skills and experience to meet the exact customers’ needs across the different markets and the growth we are seeing, speaks volumes of their capabilities.”

The German market is another one that has historically had a strategic meaning for LAG. Well-known for being uncompromising when it comes to quality, the collaborations that the company has set up with customers in the country have taught it valuable lessons and helped it to increase the calibre of its tankers. As the times are changing, however, the ways of achieving consistency in quality are shifting, too.

Rob explains: “The delivery of high-standard products now lies within our more sophisticated quality system, which is implemented throughout the entire organisation. We have initiated and executed thorough inspections at every level via our self-made ERP system to support our global supply chain and improve the efficiency of our operations.”

Another distinct advantage LAG holds over its competitors, is the strong aftersales service that defines the company. “Our support is based on the availability of a good spare parts distribution network and an extended network of service partners across the whole of Europe,” Rob details. “We can further differentiate ourselves by being able to offer big accidental repairs on tankers. What is more, we do not discriminate between brands, meaning that we also service the tankers of other manufacturers, which is being done in our self-owned workshops in Belgium, the Netherlands, and Poland.”

Going forward, Rob is noticing a growing interest for LAG’s products from traditional markets like Germany and France. “We have laid the groundwork to significantly increase our sales in Germany. Our market penetration in France is also very good at the moment, but we believe we can grow even more with certain products, such as our stainless-steel tankers and skeletons.”

The latter is seen as a sub-category where the company can expand its range not just in France, but across the entire continent. “We are market leaders for tipping skeletons and also particularly successful in the market of 20’ and 30’ container chassis for the transportation of liquid containers. We are now looking to launch a new skeleton for the transportation of general cargo containers that will feature an extendable chassis of up to 45’, whose size will help carry more goods and alleviate the traffic from some of Europe’s biggest harbours,” Rob maintains.

“We are an organisation that is aiming high and we aspire to break into top three of tanker and intermodal manufacturers in Europe within the next five years,” he outlines the long-term objective lying ahead of LAG. “To this end, we will continue to employ the most efficient production methods and invest in new manufacturing lines and robotisation to make sure we release competitive products of the highest quality. This will be done in close conjunction with our suppliers who are the cornerstone of our global supply chain strategy. Most importantly, we will always keep our customer-centric approach and the safety of our operations at the centre of our work. Our rapidly growing service network is evidence of this and we are keen to deepen our relationship with clients so we can grow together.”

LAG Trailers

Products: Tankers and intermodal vehicles