A powerful tool

Just as it wasn’t long after the discovery of X-rays that their usefulness for radiography became apparent, it wasn’t long after the discovery of the neutron by James Chadwick that its usefulness also became apparent. Neutron radiography has been proven as an extremely useful quality assurance and failure analysis tool in many industrial NDT applications where X-ray alone would fall short and is widely used by aerospace manufacturers to detect certain flaws in critical products more easily than X-rays. However, while X-rays quickly made themselves useful for industrial imaging and nondestructive testing following Wilhelm Rontgen’s discovery in the 1890s as X-ray sources became more efficient and more powerful, neutron radiography has been and continues to be hamstrung by lack of access to significantly powerful neutron sources. New advances in neutron sources can raise neutron radiography to the same level of prominence in the world of industrial NDT as X-ray imaging.

Why is neutron radiography useful?

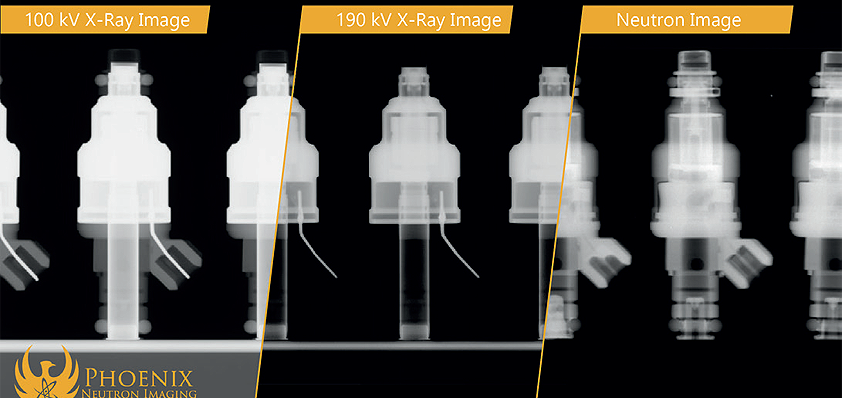

The unique physical properties of neutron radiation make it a unique tool for radiographic imaging. Neutron radiography, occasionally abbreviated as N-ray, works by the same general  mechanics as X-ray and gamma radiography. Where N-ray differs from X-ray is in its applications. There are many industrial manufacturing niches that make use of neutron radiography as an indispensable tool for quality assurance, failure analysis, and research and development. For example, in the aerospace and defense sectors, N-ray is crucial for the inspection of energetic devices such as ejection mechanisms, payload separation systems, and munitions. These devices consist of light, hydrogen-rich energetic material within a dense metal shell, which makes them very difficult to inspect using X-ray but easy to inspect using N-ray. N-ray is also one of the most powerful and efficient means to detect dangerous ceramic fragments that can remain in the cooling channels of jet engine turbine blades. In many situations in which X-ray imaging falls short, neutron radiography is a powerful complementary tool.

mechanics as X-ray and gamma radiography. Where N-ray differs from X-ray is in its applications. There are many industrial manufacturing niches that make use of neutron radiography as an indispensable tool for quality assurance, failure analysis, and research and development. For example, in the aerospace and defense sectors, N-ray is crucial for the inspection of energetic devices such as ejection mechanisms, payload separation systems, and munitions. These devices consist of light, hydrogen-rich energetic material within a dense metal shell, which makes them very difficult to inspect using X-ray but easy to inspect using N-ray. N-ray is also one of the most powerful and efficient means to detect dangerous ceramic fragments that can remain in the cooling channels of jet engine turbine blades. In many situations in which X-ray imaging falls short, neutron radiography is a powerful complementary tool.

What is neutron radiography?

Electromagnetic radiation—X-rays and gamma rays—is most typically used for industrial radiography. Electromagnetic radiation is charged photons, and its penetrative properties and utilities depend on its energy levels and wavelengths. It is affected by positive or negative charges. Neutron radiation, though, is made up of neutrons that have no charge.

The vast majority of the volume of any given atom consists of the electron cloud, where the electrons which surround the comparatively tiny nucleus reside. Electrons carry negative charges that affect electromagnetic waves, and so the more electrons an atom has—the heavier and denser the atom is—the harder it is for an electromagnetic wave to pass through it unimpeded. This is why X-rays will pass readily through your skin but less readily through bone and not at all through lead.

Neutron radiation is quite different. Because neutrons have no charge, they aren’t affected by the negative charge of an atom’s electron cloud, no matter how big it is, so a material’s neutron attenuation, or in layman’s terms how good it is at blocking or scattering neutrons, has very little to do with its density. There are many very light elements with high neutron attenuation such as hydrogen, for example, and many dense elements with very low neutron cross-sections such as lead or aluminum. Boron, for example, is one of the most neutron-absorbent elements  on the periodic table and will thus appear as highly opaque in any neutron image, but its next-door neighbors on the table attenuate neutrons much differently.

on the periodic table and will thus appear as highly opaque in any neutron image, but its next-door neighbors on the table attenuate neutrons much differently.

Neutron sources: the problems and solutions

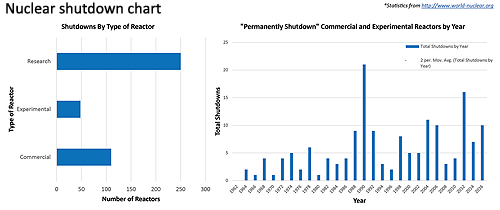

While neutron radiography was conceptually proven in the late 1930s, it was not until the 1950s when fission reactors were constructed that could provide a high enough neutron output to produce radiographic images that were clear, sharp, and detailed enough to be useful. However, over the decades, reactor neutron imaging facilities’ numbers have dwindled in line with decreasing numbers of nuclear facilities in general, straining supply chains for manufacturers who rely on neutron radiography.

For example, when Aerotest Operations, a reactor facility that had een the primary source of neutron radiography services for aerospace manufacturers since the 1980s, had to shut down due to an unexpected licensing issue, the effects on the neutron imaging supply chain were catastrophic. Many manufacturers were either left scrambling to find other vendors or abandon neutron radiography altogether. As a result, neutron radiography is underused in niches where it can do the most good, and many of its possible usages in other sectors, such as automotive manufacturing, have been severely underexplored.

A promising supplement for fission reactors as a neutron source is particle accelerators as a neutron source. Exploring alternative neutron sources will make it easier for both for current users of this powerful nondestructive inspection method to continue using it and for its use to expand into new manufacturing industries.

Willow Ascenzo

Willow Ascenzo is a Copywriter and Content Creator for Phoenix. Founded in Madison, Wisconsin in 2005, Phoenix, LLC. designs and manufactures the world’s strongest accelerator-based high-flux neutron generators. Phoenix’s cutting-edge nuclear technology has been used in the aerospace, defense, medical and energy sectors to improve manufacturing efficiency and quality. Since 2012, Phoenix has designed and delivered neutron generators for a wide range of practical purposes including neutron radiography, nuclear fuel inspection, and medical isotope production.

https://phoenixwi.com/