Building Trust: The Strategic Growth Journey of APCT

For Steve Robinson, a relationship with a customer is like a marriage. “Ultimately, regardless of how upset [your spouse] gets, there’s a trust you have with them that allows you to work through any situation,” says the CEO and president of APCT. “That is what we strive for with our customers: the passion and commitment to develop that level of intimacy and trust. When you earn that trust, you have a potential long term relationship.”

So before bringing new family members into that customer relationship, Robinson wants to ensure they share APCT’s values. When evaluating a potential acquisition, he looks not only at the facility’s capabilities but also its people. Are they customer focused, service oriented and ready to elevate themselves? “In any acquisition, you can buy a facility. But it’s really the people inside the facility that you’re buying,” Robinson says. “You have to be diligent to make sure you have the culture and environment to seamlessly integrate those sites.”

Not every opportunity passes those criteria. “Sometimes it’s a challenge embracing a service business,” Robinson says. “You really test the company’s culture and strength as you start to acquire and integrate other facilities.”

Capacity and Capability

APCT has been in continuous growth mode since the day Robinson purchased the company in 2008. However, there are physical limits that can stymie growth. By 2016, APCT’s manufacturing facility in Santa Clara, Calif., was already nearing peak capacity and the company needed to quickly expand its footprint to meet accelerating customer demand. In the last two years, APCT purchased a manufacturing site in Wallingford, CTonn., and two plants in Southern California. It also built an inventory control distribution facility in Austin, Texas.

The additions were strategic decisions designed to help APCT keep pace with its customers. The company has seen explosive growth on the East Coast, necessitating a new facility to maintain APCT’s speed advantage. At the same time, APCT began to think about other markets it could enter. In January, the company purchased two companies in Orange County, Calif.: Cartel Electronics and its affiliate, Cirtech, the latter giving APCT access to the flex / rigid-flex market place.

The acquisition fit APCT’s other goal: to broaden its range of products. “As you look at the North American market, the one area that really tracked with growth was advanced technology,” Robinson says. “We believe the acquisition would be strategic and the technology would provide a high level of value to that customer base.”

Flex and rigid/flex circuit boards are ideal solutions for advanced electronic products that are designed to condense components into the smallest possible footprint. Before the acquisition, Cirtech had supplied flexible and rigid-flex circuit boards to military and Tier I suppliers, many of which have continued their relationships with APCT. “There was a continued interest from all of them in our DNA and our culture of speed to have us make flexible circuit boards,” Robinson notes.

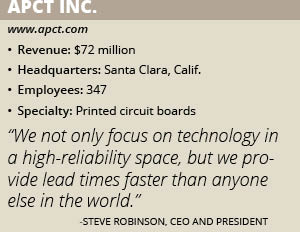

In the wake of the acquisitions, APCT has become one of the largest privately held printed circuit board manufacturers in North America with 347 employees and $75 million in annual revenue. Although 90 percent of its business remains in the United States, it now ships around the world to more than 700 Tier I, II and III customers.

In the wake of the acquisitions, APCT has become one of the largest privately held printed circuit board manufacturers in North America with 347 employees and $75 million in annual revenue. Although 90 percent of its business remains in the United States, it now ships around the world to more than 700 Tier I, II and III customers.

“To grow the way we have requires customer appreciation,” Robinson says. “On a daily basis, we drive relentlessly with passion and commitment to earn a customer’s trust. If you can achieve customer trust, you ultimately have the ability to expand, to nurture the relationship with the customer.”

Supporting Customers

Electronics manufacturing is a precise and complicated process. It can take an OEM years to match technological innovation with consumer-friendly design and it is common to fall behind schedule. Manufacturers are increasingly looking to their suppliers for help in catching up. APCT provides engineering resources and fast fulfillment – its lead times are consistently faster than industry standards – to shorten the length of those disruptions and get clients back on schedule. “The speed ability we offer allows customers to recover delays,” Robinson says.

“We not only focus on that technology in a high-reliability space, but we provide lead times faster than anyone else in the world,” he continues.

APCT’s speed, combined with its innovation and reliability, has strengthened its foothold with its customers. The company used to mostly provide circuit boards for initial products. But as it has increased its capabilities it has seen higher growth in the second stage of the product lifecycle, when production ramps up and the client must move to full production ordering.

“Velocity is our core competency and I will make sure that’s always our priority,” Robinson says.

Maintaining that speed as APCT grows requires constant reinvestment. This year, the company is investing $4.5 million to add capital equipment at both of its new facilities in Orange County. A large chunk of that investment will be for multiple laser direct imaging (LDI) machines, which offer better quality, more precision and faster production than traditional photo processing for printed circuit boards. “It really takes them to another level of efficiency,” Robinson says. “If you want to support the technology space you have to have the tools.”

Having the right tools is important to provide the capability customers need, but APCT also needs to have the right tool operators. The company is already running 24/7 shifts at three of its plants and is in the process of adding a third shift to the former Cirtech facility.

Although much of its expansion focus has been on its new facilities, APCT continues to make improvements at its headquarters in Santa Clara as well. Because many of the products it supports are first generation, APCT has a team of in-house design for manufacturability (DFM) engineers that work with customers to develop their devices.

That team is located in Santa Clara. Because the core competency of the company is detailed engineering support enabling superior execution, expansion of the DFM team was critical. The company moved its administration purchasing and outside sales organizations to a separate building adjacent to the manufacturing plant and used that space to add six more DFM engineers. “We freed up more space to put in more front-end engineering and DFM,” Robinson says.

Those investments will help APCT reach its goal of $100 million in annual revenue. That is large enough to leverage its purchasing power in the supply chain, but still small enough to be nimble and focused on its core competencies.

“We have to remain flexible,” Robinson says. “We have to be able to change directions. We have to continue to be user-friendly.”