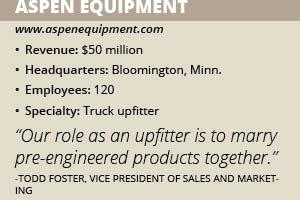

Aspen Equipment

Assembling all the components for a truck-mounted crane or a highway plow truck requires coordination among as many as 40 different manufacturers to create a vehicle that efficiently blends utility with safety. It’s a complicated process that demands strong organization and communication.

Aspen Equipment, a leading truck upfitter, borrows from the construction industry and approaches the process with a project manager structure. The project manager is responsible for managing all the vendors and equipment manufacturers, funneling them to a single vision for the final vehicle’s capabilities. “That’s in essence what we do,” Vice President of Sales and Marketing Todd Foster says. “We’re designing and constructing a building, but instead it’s a truck.”

Aspen’s heritage dates back to 1926 with the founding of Road Machinery & Supplies Co., a mining and construction equipment distributor. Aspen started as a division of Road Machinery focused primarily on smaller construction equipment such as air compressors and compactors for the construction industry.

In 1994, the Aspen and Reach Equipment divisions of Road Machinery were merged and formed into an independent company under the Aspen Equipment name. After the formation of the new company its focus was on the final stage manufacturing of vocational trucks.

The company assembles 1,500 to 2,000 work trucks annually in 90,000 100,000 square feet of production space divided between its headquarters in Bloomington, Minn., and its other facilities in Omaha, Neb., and Des Moines, Iowa. Production time for vehicles varies greatly depending on its type: a work van interior with shelving and tool racks can take six hours while a custom mining truck can require 600 hours to complete.

More than 40 major product lines are used in Aspen vehicles, including National Crane, Henderson plows, Palfinger cranes, Elliot aerials, Bibeau dump bodies and mobile hydraulics cranes from Manitowoc/Grove. That range of equipment providers enables Aspen to serve a diverse group of customers, including the construction, municipal, material-handling, railroad and forestry industries.

Our role as an upfitter is to marry pre-engineered products together,” Foster says. For a single vehicle, Aspen might take a crane from one manufacturer, hydraulic system from another and the body from a third. Aspen’s product designers then work with their counterparts at each of those suppliers to turn those individual pieces into one coherent tool. The complexity of the resulting vehicle and its work functions depend on the vocation and the customer’s requirements.

Translating Requirements

Determining those requirements is the starting point for the entire process. “It’s not necessarily ‘what kind of truck do you want?’ But ‘what is the job you need done?’” Foster says. Aspen’s salespeople are responsible for finding customers in need of equipment the company can provide and then working with the client to determine initial requirements. “Our sales team will sit down with a customer in need of getting a job done,” he adds. “We’ll help design it, quote it and build it.”

From those initial discussions, Aspen’s design team calculates weight balance and makes cost projections, recommends features the client may not have thought of and develops a  preliminary drawing to create a proposal and quote. Once the customer accepts the proposal, Aspen finalizes the design and determines the bill of materials. “It’s really the designer’s job to take what the customer wants and translate that to our production employees so they can build what the customer is asking,” Foster says.

preliminary drawing to create a proposal and quote. Once the customer accepts the proposal, Aspen finalizes the design and determines the bill of materials. “It’s really the designer’s job to take what the customer wants and translate that to our production employees so they can build what the customer is asking,” Foster says.

“The challenge is creating the marriage between all the different pieces to make it work,” Foster continues. A customer might need to place a 200-foot lift from Bronto Skylift or a 60 ton crane from National Crane on the back of the truck, for example. Fitting such large pieces of machinery on a mobile chassis is difficult in of itself, but Aspen must also take care to keep the vehicles as light as possible so that they do not violate weight limits put in place by federal bridge regulations and state standards. “We have to design a trucks that will not only make it from here to Texas but make it legal in Texas,” Foster says.

Balancing those requirements with proper weight distribution and safety necessitates strong collaboration between Aspen and its suppliers. The company uses many highly regarded manufacturers and puts a premium on quality. “We’re not the low-price producer by any stretch,” Foster says. “We focus on products that are high quality and will last for customers.”

Training Talent

Aspen’s diverse customer base is its biggest strength. When the Great Recession took hold in late 2007, the decline in the housing market halted the construction industry. Demand for Aspen’s construction cranes and other vehicles dried up, but the decline was offset by growth in the railroad and municipal snowplow segments.

Diversity also poses one of Aspen’s largest challenges. Because it serves so many different industries, it can be difficult to find common components or designs between vehicles. To become more efficient, Aspen began thinking of its trucks as made up of individual building blocks. “You can build just about anything with Legos but all the individual pieces are the essentially the same,” Foster says. “So if you break those pieces down you can use standards for a custom built.”

At first glance a stake body truck doesn’t have much in common with a 60-ton mobile crane, but both vehicles might share a common tow hitch, lighting package or toolbox mount. “Those standards help ensure quality because we really guide the techs on ‘this is the most efficient way to install it and this is how you install it,’” he explains.

It’s not enough to simply offer different kinds of equipment; Aspen’s production workers and designers also must be skilled in meeting the needs of those diverse industries. The company instituted a new training program in 2015 that brings in outside experts to conduct teaching sessions for employees at Aspen’s in-house classroom. From there, the lessons continue on the shop floor. At the end of the program, employees not only learn a skill that complements their role at Aspen, but can earn certifications in areas such as welding that they then carry with them throughout their career.

The training program is designed to elevate employees’ skills while making a job at Aspen more lucrative. Like many manufacturers, the company has struggled to find the qualified workers it needs to support its growth. Recruitment into the industry is a contributing factor to that challenge, so Aspen has begun working with local high schools to introduce students to technical careers.

“Finding talent is difficult, keeping talent is sometimes even more difficult,” Foster says. “It’s important for us to provide an environment where people can grow.”