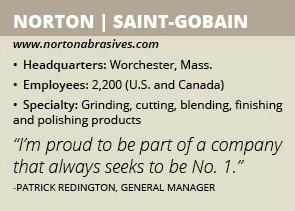

Norton | Saint-Gobain

After more than 130 years, Norton | Saint-Gobain has a reputation for bringing state-of-the-art technologies to the abrasives industry. “We’ve always been on the cutting-edge of innovation,” declares Patrick Redington, the company’s general manager of Technical Markets & Application Engineering North America.

Based in Worcester, Mass., Norton offers a broad portfolio of grinding, cutting, blending, finishing and polishing products. The company started operations in 1885 and today is a part of Saint-Gobain Abrasives, the world’s leading manufacturer of abrasives.

Lines, Redington notes, include its bonded abrasive grinding wheels, its coated abrasives belts and discs, and Superabrasives. Its super abrasives, he notes, offer higher performance than its bonded products, thanks to the inclusion of diamond and cubic boron nitrate(cBN) into its premium bond systems.

The company serves all automobile manufacturers, including Ford Motor Co. and General Motors, as well as engine components companies. “Almost every functional manufactured component in your automobile drivetrain is ground,” Redington says. “We’re very, very strong in the grinding of camshafts, crankshafts, steering components and the drivetrain itself.”

Norton also serves companies in the aerospace industry, including General Electric, Pratt & Whitney and Rolls-Royce, along with bearing and gear companies. “Our other major clients would be the cutting tool industries,” he says. “Our products are used in almost in every industrial market that you can think of.”

Flavors of the Business

Redington joined Norton 28 years ago. “I started in R&D,” he recalls. Over the years, he worked his way through the company’s manufacturing, product management, sales and marketing departments before entering management.

It is common for managers to move up through the ranks. “We like to give people a flavor for all the different aspects of the business,” he says.

The company’s focus on innovation has driven its success, Redington says. This has led to the development of its Seeded Gel (SG) technology, which is a ceramic alumina that cuts faster and lasts up to 500 percent longer than standard abrasives. “It is proving very successful in the industry,” he says.

Redington also is proud of Paradigm, a porous hybrid metal bond system for diamond grinding wheels that secures the diamonds in place. “It gives our customer value by offering a longer life, higher productivity, better surface finish and surface integrity,” he says. “We’ve been testing the same technology for next-generation aerospace grinding.”

Meeting Needs

Meeting Needs

Clients are asking for more connectivity in their tools, which the company is striving to fulfill. “Most of our customers want to be able to measure and predict grinding performance,” Redington says.

So far, the company met this need with the development of a Field Instrument System (FIS) that can easily plug into its equipment and measure power and displacement over time. “The other big challenges we’re seeing is our customers’ continuous demand for better tolerances, finer finishes and lower costs,” he reports.

Norton is meeting that need by partnering with them. “We will work with these companies and help them define these problem areas to reduce their total costs,” Redington says, adding that these could involve such metrics as cycle time reduction, quality improvements and reduced rework.

World-Class Work

Norton places a strong focus on manufacturing quality through World Class Manufacturing (WCM), an internal program. The program, which is throughout Saint-Gobain’s operations, is inspired by lean and Six Sigma techniques, Redington says.

Through WCM, Norton drives quality objectives as well as loss deployment initiatives so it can examine where it did not meet expectations on a project. “We go through a series of steps and protocols to define what the problem was and fix it,” he says.

Another important aspect of WCM is people development, where it provides training for its factory employees and engineers, who can earn yellow and green belts.

“We also have a strong training program for our new salespeople and last, but not least, training for our customers,” he adds.

The training teaches clients on how to apply its products to solve problems and improve their grinding processes. “If we do that, these customers will become successful and stay loyal to our brand long-term, because they know we’ll support their future total cost reduction goals.” Redington says.

This is embodied in the company’s Process Solution Program (PSP) where it works with customers side-by-side to develop new processes and optimizes existing ones. “This has been a very successful program for Norton globally,” he adds.

Norton Pride

After nearly three decades, Redington is proud of the way Norton puts the customer first, particularly through its PSP program. “[We look at] what are their pain points and how we can help them,” he says.

He also takes pride in community contributions, which include working with groups like the United Way and YouthBuild. “Being part of a company that wants to be part of the community is very rewarding,” Redington says.

The company also strives to be an industry leader. “We want to provide the full range of products and the best products,” he says. “I’m proud to be part of a company that always seeks to be No. 1.”

Redington sees more success for Norton. “I think grinding is always going to have a place and we’ll continue to grow,” he says, noting that more, high performance stronger materials are being developed.

“All of these materials are going to be difficult to process by traditional methods like turning and milling. Grinding is a very efficient and cost effective method to process these materials,” Redington says. “These new materials are going to be the way of the future, whether they’re ceramics, ceramics composites or diamonds themselves.”

Additionally, as industries turn to greener technologies,“They’ll want more efficient processes and more efficient components as well,” Redington continues. “That’s going to drive tighter tolerances. The future is bright for the grinding industry and grinding processes.”