Top 5 automated production systems

In recent years, the world has seen significant advancements in automation technologies, leading to the development of various automated production systems.

These have since become an integral part of modern manufacturing processes. Automation has transformed the manufacturing industry, making it more efficient, accurate, and cost-effective.

But what are the top five automated production systems? Read on to find out.

1. Industrial robotics

One of the most popular automated production systems used in modern manufacturing is industrial robots for tasks such as welding, painting, assembling, and packaging.

These robots are programmed to perform specific tasks with high precision and accuracy. They can work tirelessly for long hours without the need for breaks, making them more efficient than human labor.

Industrial robots can also work in hazardous environments, reducing the risk of accidents and injuries.

2. Automated Guided Vehicles

Automated Guided Vehicles (AGVs) are self-driving vehicles that are used to transport goods in factories and warehouses. These vehicles use sensors and navigation systems to move around and avoid obstacles so there are no crashes!

They are programmed to transport goods from one location to another without the need for human intervention. AGVs are designed to work in various environments, including cleanrooms and hazardous areas, making them an ideal solution for many manufacturing processes.

3. Conveyor systems

Conveyor systems are used to transport materials and products from one location to another in a manufacturing plant. They are commonly used in assembly lines to transport products from one station to another, which makes them more location specific than AGVs.

Conveyor systems can be fully automated, reducing the need for human intervention. They can also be customized to fit different manufacturing processes, making them an ideal solution for various industries.

4. 3D printing

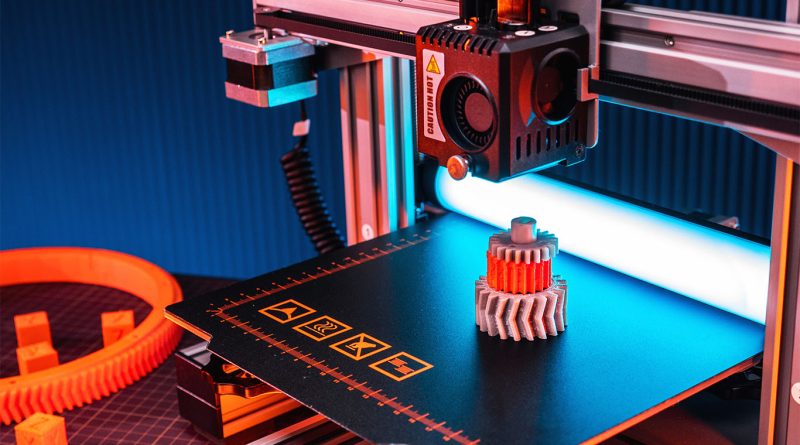

3D printing is a technology that involves the creation of three-dimensional objects from a digital file. It is used in various industries, including manufacturing, aerospace, and healthcare.

3D printing is an automated production system that can produce complex shapes and geometries that cannot be otherwise produced using traditional manufacturing processes. It is also cost-effective and reduces waste, making it an eco-friendly solution.

5. Automated Inspection Systems

Last but not least, automated inspection systems are used to inspect products and materials during the manufacturing process. These systems use sensors and cameras to detect defects, such as cracks and surface imperfections.

Automated inspection systems can perform inspections at high speeds and with high accuracy, reducing the need for human intervention. They can also be integrated with other automated production systems, such as industrial robotics and conveyor systems, creating a integrated and automated production process.

The advent of automation technologies has revolutionized modern manufacturing, offering a plethora of automated production systems to enhance efficiency, accuracy, and cost-effectiveness. The top five automated production systems outlined represent a diverse range of solutions catering to different manufacturing needs. These systems not only streamline processes but also contribute to safer working environments, reduced labor costs, and increased productivity.